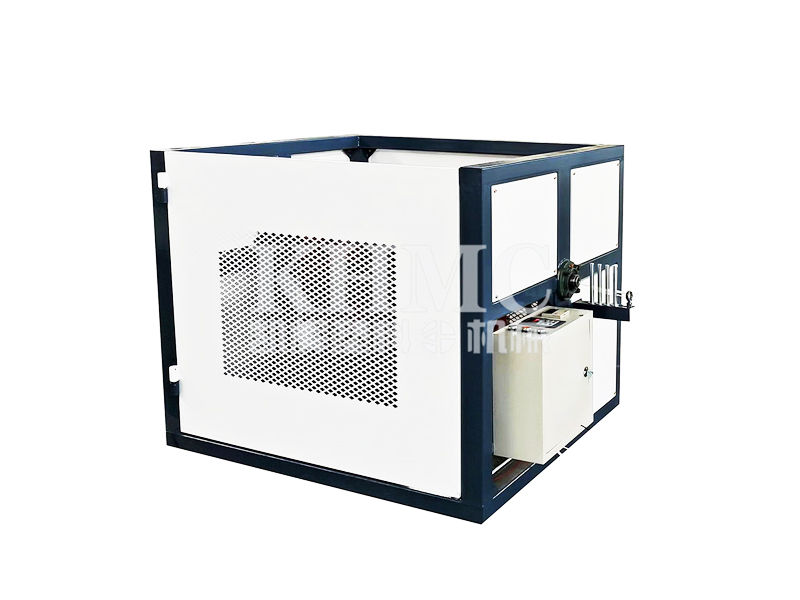

High Quality PP Baler Twine Making Machine With Stable Performance

Technical Parameters

| Type |

KHSJ-E65 |

KHSJ-E80 |

KHSJ-E90 |

KHSJ-E110 |

KHSJ-E125 |

KHSJ-E140 |

KHSJ-E160 |

|

| Screw Diameter(mm) |

65 |

80 |

90 |

110 |

125 |

140 |

160 |

|

| Gross power (kw) |

75 |

85 |

97 |

106 |

114 |

123 |

142 |

|

| Actual power consumption (kw) |

30 |

36 |

41 |

49 |

52 |

62 |

71 |

|

| Productivity(kg/h) |

40-50 |

60-80 |

80-100 |

100-130 |

125-140 |

135-180 |

170-210 |

|

| Dimensions(m) |

L: 20-25, W: 2-3, H: 2-3 |

|||||||

|

It can be designed according to workshop size. |

||||||||

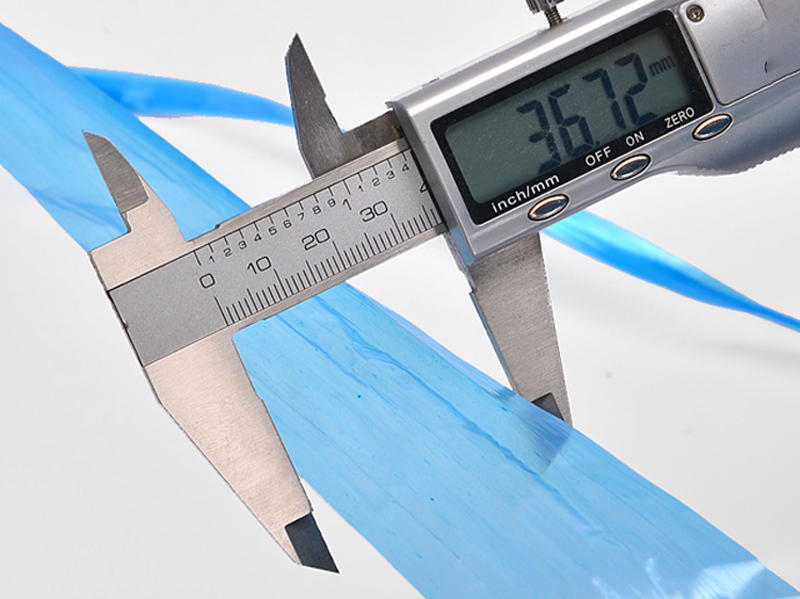

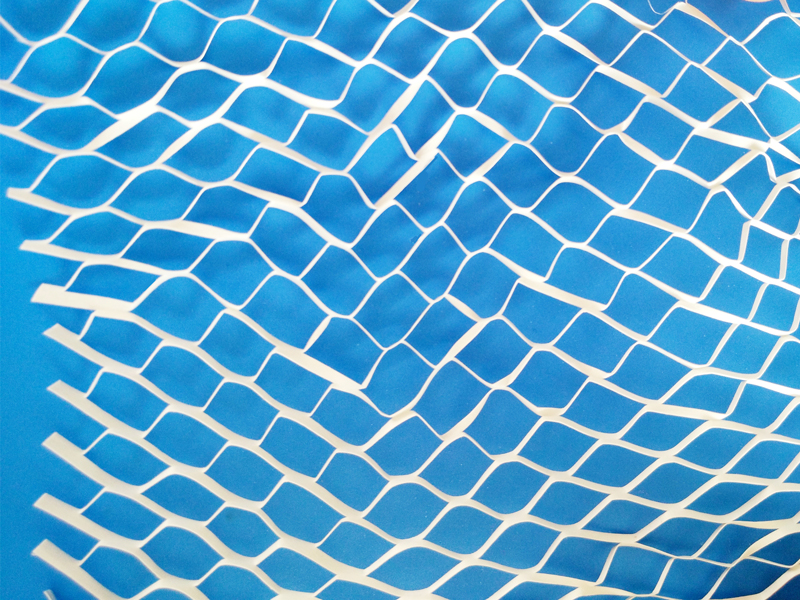

Finished Products

The finished twine is call differently in different areas, like raffia, string, sutli, hay baler twine, tear film, split film, flat yarn,thread, etc. The production line can work with ball winder or bobbin winder to make the baler twine into ball or spool shape. It can also work with twisters to make twisted twine.

Product Video

Advantages of Equipment

Our equipment has been specially processed to better adapt to various forms of raw materials, such as waste plastic films, hard plastic sheets, plastic granules, plastic powder, etc. No matter you use pure new material or recycled material, our machine can function well to make good quality products that meets the standards required by customers. Usage of recycled materials, especially the use of flakes and powders, greatly reduces the cost of raw materials and increases the profit of customers. Our machine therefore receives many good reviews from customers all over the world.