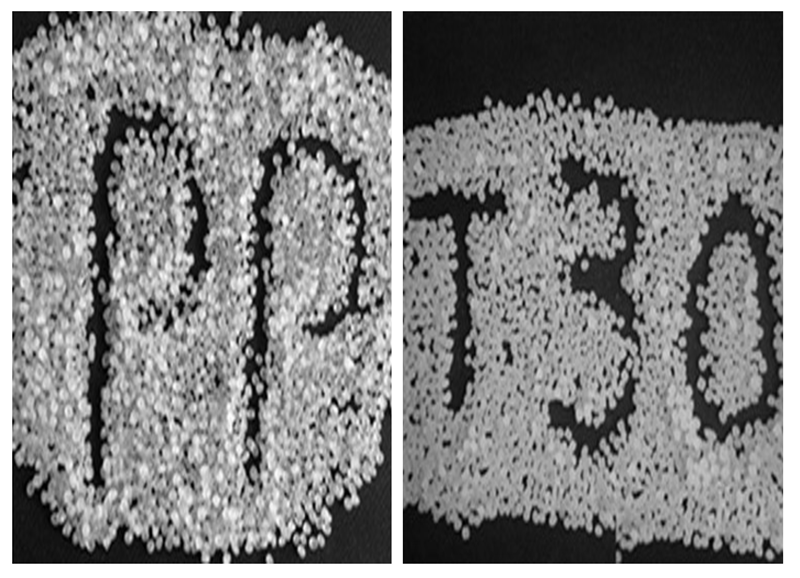

30s is a specification of polypropylene, mainly used in the production of membrane crack fiber (agricultural rope, string, spinning, etc.) monofilament, stretch film, tube film, etc. T30s is the lightest of the general-purpose resins, with good rigidity, light transmission, corrosion resistance, electrical insulation, thermal fluidity, and dimensional stability, excellent mechanical properties, and good heat resistance. For the plastic extruding machines made by our factory which use pp materials, the pp used are all T30s model.

T30s melting point is about 170°c. It is stable without deformation under 150°c if there is no external force. It is chemically stable, resistant to acids, alkalis, and organic solvents. It does not interact with most chemicals and basically absorbs no water. Its disadvantage is easy embrittlement and poor impact strength at low temperature. However, its disadvantages can be improved by additive blending or copolymerization. Its melt flow rate is 2-4, and its density is 0.9-0.91. Different countries and regions have different numbers for polypropylene, but as long as the parameters are the same, its characteristics and applications are also the same.

Polypropylene has chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and good high wear resistance processability, which has made polypropylene widely developed and applied in many fields such as machinery, automobiles, electronic appliances, construction, textile, packaging, agriculture, forestry and fishery and food industry since its inception.

Welcome to contact KHMC to get more information about all types of plastic machineries and plastic materials. With 30 years’ experience in the plastic industry, we will always give you the most proper suggestion.

Post time: Oct-18-2022