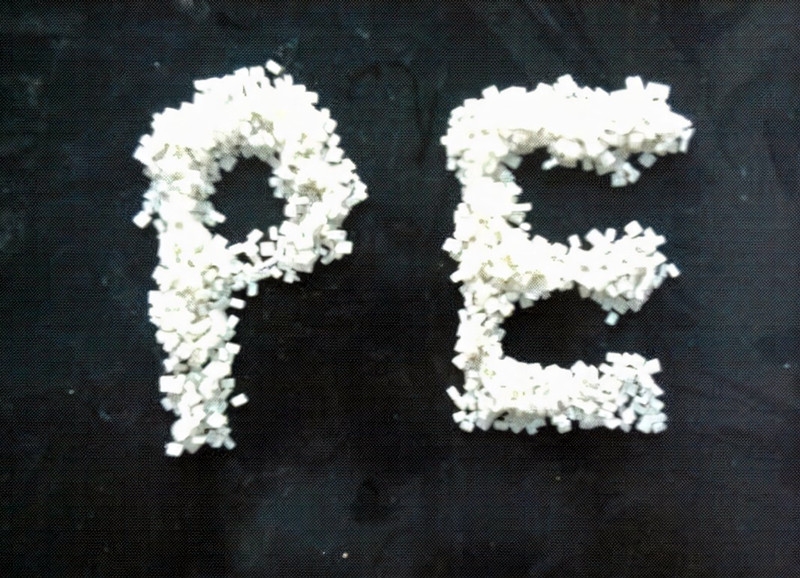

1. High-density polyethylene (HDPE)

HDPE is non-toxic, tasteless and odorless, with a density of 0.940-0.976g/cm3. It is the product of polymerization under low pressure under the catalysis of Ziegler catalyst, so high density polyethylene is also called low pressure polyethylene.

Advantage:

HDPE is a kind of thermoplastic resin with high crystallinity and non-polarity formed by the copolymerization of ethylene. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. It has excellent resistance to most household and industrial chemicals, and it can resist corrosion and dissolution of strong oxidants (concentrated nitric acid), acid-base salts and organic solvents (carbon tetrachloride). The polymer is non-hygroscopic and has good water vapor resistance and can be used for moisture and seepage resistance.

Shortcoming:

The disadvantage is that its aging resistance and environmental stress cracking are not as good as LDPE, especially thermal oxidation will reduce its performance, so HDPE adds antioxidants and UV absorbers when it is made into plastic coils to improve its performance. shortcomings.

2. Low-density polyethylene (LDPE)

LDPE is non-toxic, tasteless and odorless, with a density of 0.910-0.940g/cm3. It is polymerized with oxygen or organic peroxide as a catalyst under high pressure of 100-300MPa. It is also called high-pressure polyethylene. LDPE is generally referred to as PE pipe in the irrigation industry.

Advantage:

Low-density polyethylene is the lightest variety of polyethylene resins. Compared with HDPE, its crystallinity (55%-65%) and softening point (90-100℃) are lower; it has good flexibility, extensibility, transparency, cold resistance and processability; its chemical Good stability, acid, alkali and salt aqueous solution; good electrical insulation and air permeability; low water absorption; easy to burn. It is soft in nature and has good extensibility, electrical insulation, chemical stability, processing performance and low temperature resistance (can withstand -70 ° C).

Shortcoming:

The disadvantage is that its mechanical strength, moisture barrier, gas barrier and solvent resistance are poor. The molecular structure is not regular enough, the crystallinity (55%-65%) is low, and the crystalline melting point (108-126°C) is also low. Its mechanical strength is lower than that of high-density polyethylene, and its impermeability coefficient, heat resistance and sunlight aging resistance are poor. Antioxidants and UV absorbers are added to remedy its deficiencies.

Post time: Aug-17-2022