Wholesale Ring Twisting Machine – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery

Wholesale Ring Twisting Machine – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery Detail:

Technical Parameters

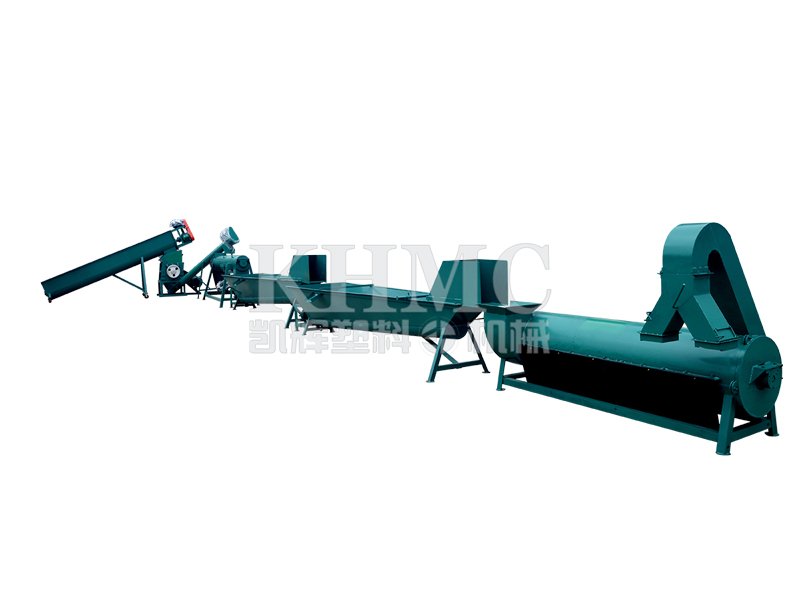

|

Conveyor |

Label remover |

Conveyor |

Screw feeder |

Crusher |

|

|

Power |

1.5kw |

15kw |

1.5kw |

4kw |

22kw |

|

Size |

4m*0.7m |

4m*Φ0.63m |

4m*0.7m |

4m*0.5m |

#612 |

|

Screw Loader |

Frictional washer |

1st Floating washer |

2nd Floating washer |

Water extractor |

|

|

Power |

2.2kw-6 |

7.5kw |

2.2-4kw |

2.2-4kw |

15kw |

|

Size |

3m*Φ0.219m |

3m*Φ0.377m |

4m*1m |

4m*1m |

2.5m*Φ0.56m |

Function

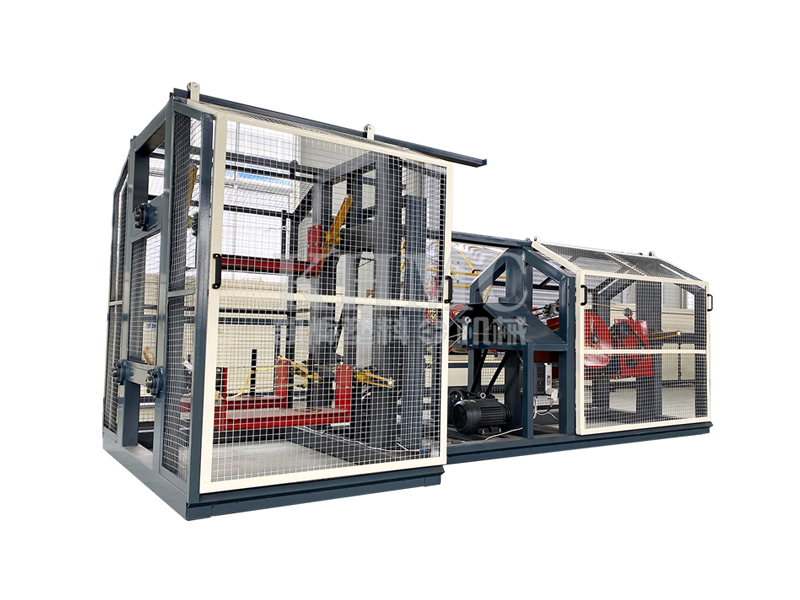

The pet bottle recycling machine can produce pet flakes by a working process of label moving—crushing—washing—drying. Meanwhile, as the water bottle is made of PET, while the cap is made of PE, the cap flakes is also a very high-quality recycled raw material as a by-product of the production line. It can be directly mixed into PE granules to produce PE products, or to be processed into granules to improve product quality and added value.

Classification

The pet bottle recycling line has two types, cold washing type and hot washing type.

Cold washing – As the name suggests, the water used for washing is cold water at room temperature. The equipment cost is relatively low, and the finished product flakes can be used to produce plastic rope, brush wire, etc.

Hot washing – Compared with cold washing, the equipment has a heating furnace to increase the temperature of the washing water, and the produced flakes are cleaner, especially suitable for dirty raw materials containing grease and sundries. The finished products are mainly used for chemical fiber processing and textile industry.

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Wholesale Ring Twisting Machine – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery , The product will supply to all over the world, such as: Croatia, Liverpool, Thailand, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!