Wholesale Pp Strapping Band Making Machine Supplier – Cost-Effective M Type 3/4 Strand Rope Twisting Machine – Kaihui Machinery

Wholesale Pp Strapping Band Making Machine Supplier – Cost-Effective M Type 3/4 Strand Rope Twisting Machine – Kaihui Machinery Detail:

Technical Parameters

|

Model |

M88 |

M77 |

M66 |

M55 |

M44 |

M33 |

|

Speed |

300r/min |

320r/min |

350r/min |

420r/min |

620r/min |

900r/min |

|

Rope Diameter |

32-40mm |

26-32mm |

20-26mm |

14 -20mm |

8 -14mm |

3 -8mm |

|

Direction |

s/z |

s/z |

s/z |

s/z |

s/z |

s/z |

|

Motor power |

30KW-6 |

22KW-6 |

18.5KW-6 |

7.5KW-6 |

5.5KW-4 |

4KW-4 |

|

Dimension(m) |

14*2.1*2.1 |

12*2.1* 2.1 |

9.2*2.1*2.1 |

7.8* 2*2 |

5.2*1.9*1.9 |

4.2*1.9*1.9 |

|

Output(t/day) |

2.5-3 |

1.8-2.5 |

1.3-1.8 |

1-1.3 |

0.8-1 |

0.2-0.8 |

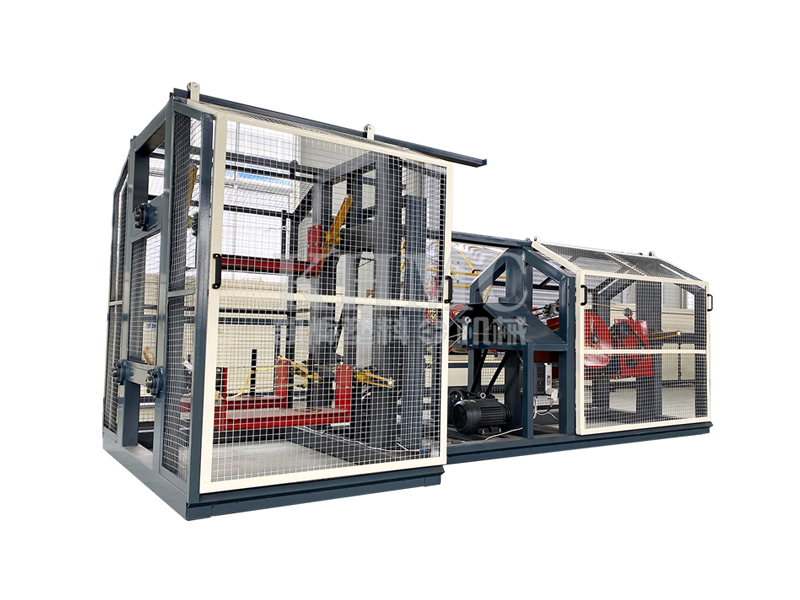

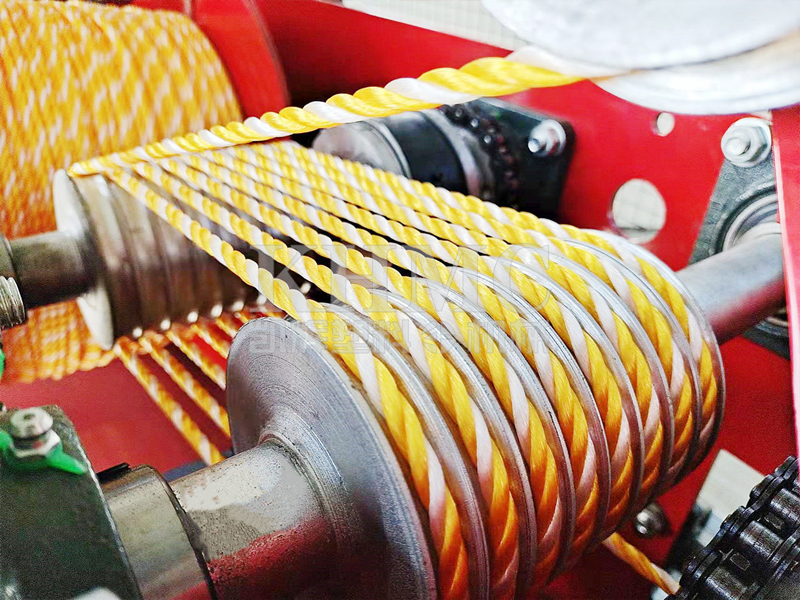

Function

This machine is suitable to make ropes with different materials, like plastic monofilament rope, plastic flat rope, danline rope, nylon rope, film rope, jute rope, cotton rope, hemp rope, etc. It can work with the coiling machine to make the ropes into small coils.

Product Video

Technical Improvement

The machine replaces the machines which make ropes by two processes of single twisting and single plying separately in the past. Twisting and plying are completed on this same machine, which greatly reduces labor costs.

Since the equipment is a high-speed rotating machine, the rope-making machine produced by our company is equipped with an induction door. Doors are switches. When the door is opened, the machine stops running; when the door is closed, the machine automatically continues to work. This effectively avoids the possible injury caused by the wrong operation of the workers, and meets the safety technical indicators.

The twist degree of both the single twist and the twisted rope can be adjusted, and the tightness of the winding can be adjusted as well. The machine, therefore, can meet the needs of different end customers’ need.

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Wholesale Pp Strapping Band Making Machine Supplier – Cost-Effective M Type 3/4 Strand Rope Twisting Machine – Kaihui Machinery , The product will supply to all over the world, such as: Peru, Hamburg, Romania, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.