Wholesale 10 Spindles Automatic Wool Yarn Ball Winder Machine How to Winder Wool Thread to Be Ball Shape

Dedicated to strict high-quality regulate and considerate shopper service, our experienced staff members users are constantly available to discuss your necessities and assure full buyer pleasure for Wholesale 10 Spindles Automatic Wool Yarn Ball Winder Machine How to Winder Wool Thread to Be Ball Shape, Should further information be required, please contact us at any time!

Dedicated to strict high-quality regulate and considerate shopper service, our experienced staff members users are constantly available to discuss your necessities and assure full buyer pleasure for China Machine and Winder, Customer’s satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we’re doing for. We’re an absolutely reliable partner in your case in China. Of course, other services, like consulting, can be offered too.

Technical Parameters

| Model |

SA-O06/N(U) |

SA-O10/N(U) |

SA-O12/N(U) |

|

Spindle No |

6 spindles |

10 spindles | 12 spindles |

|

Ball Weigh |

10-200g | ||

|

Motor Power |

750w |

||

|

Rotation Rate |

1450 r/min |

||

| Machine Size |

2.3*0.7*1.1M |

2.8*0.7*1.1M |

3.3*0.7*1.1M |

| Machine Weight |

390KW |

420KG |

450KG |

| Voltage |

380V, 220V or customized |

||

|

Applicable Materials |

Plastic, Fiber, Wool, Cotton, Paper, Jute, Sisal hemp, Chenille, Manila, Acrylic, etc. |

||

Customization

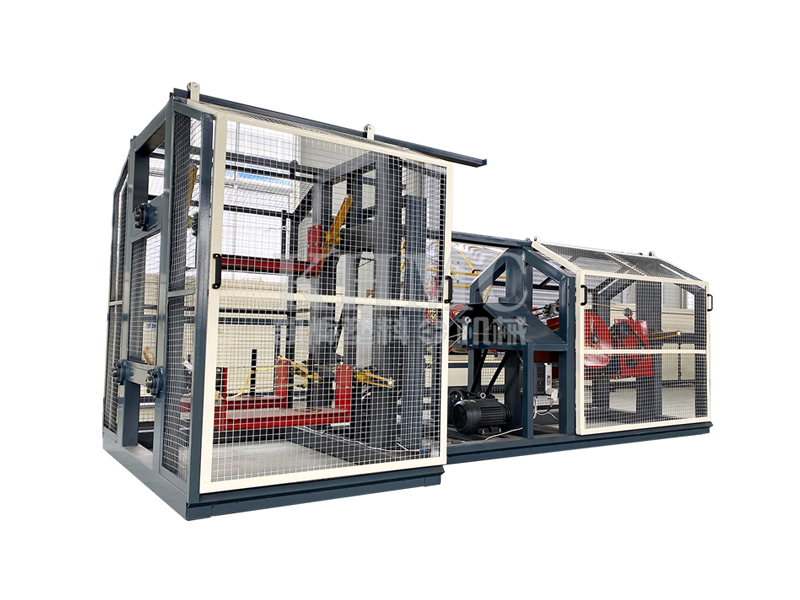

The machine is customizable with spindle numbers. 10 & 12 spindles are most popular, 4 spindles, 6 spindles, 20 spindles or other customized spindle quantity are also available.

Function

The thread ball making machine is suitable for different materials such as Plastic, Fiber, Wool, Cotton, Paper Jute Chenille, Manila, Acrylic, etc. The winder can make the filament into both ball shape and cross shape.

Installation and Operation

This rope ball winder is easy to operate. Our company provides a full set of installation and operation videos and instruction manuals to help customers standardize their use behavior. It is very easy to learn. Customers are welcomed to provide sample to test to find the most suitable machine to make proper products, saving time, saving costs, thereby increasing profit margins.

More Choices

There are two types of ball winding machines are available. For the independent controlling system type, we can do single spindle, double spindles, four spindles, five spindles or more. For the shared controlling system type, we normally do 10 or 12 spindles. We can also provide customized machinery according to your needs.

Product Video

Bottom price China Machine and Winder, Customer’s satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we’re doing for. We’re an absolutely reliable partner in your case in China. Of course, other services, like consulting, can be offered too.