High-Quality Yarn Balling Machine Factory – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery

High-Quality Yarn Balling Machine Factory – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery Detail:

Technical Parameters

|

Conveyor |

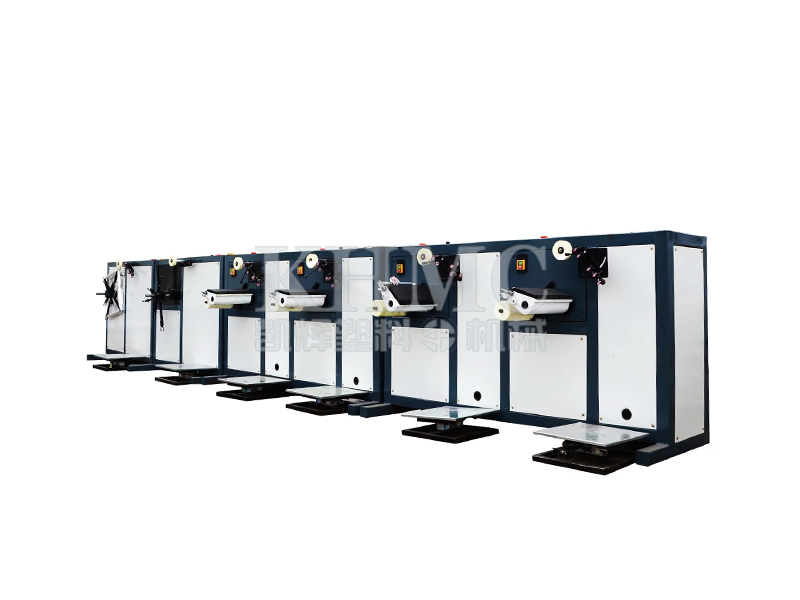

Label remover |

Conveyor |

Screw feeder |

Crusher |

|

|

Power |

1.5kw |

15kw |

1.5kw |

4kw |

22kw |

|

Size |

4m*0.7m |

4m*Φ0.63m |

4m*0.7m |

4m*0.5m |

#612 |

|

Screw Loader |

Frictional washer |

1st Floating washer |

2nd Floating washer |

Water extractor |

|

|

Power |

2.2kw-6 |

7.5kw |

2.2-4kw |

2.2-4kw |

15kw |

|

Size |

3m*Φ0.219m |

3m*Φ0.377m |

4m*1m |

4m*1m |

2.5m*Φ0.56m |

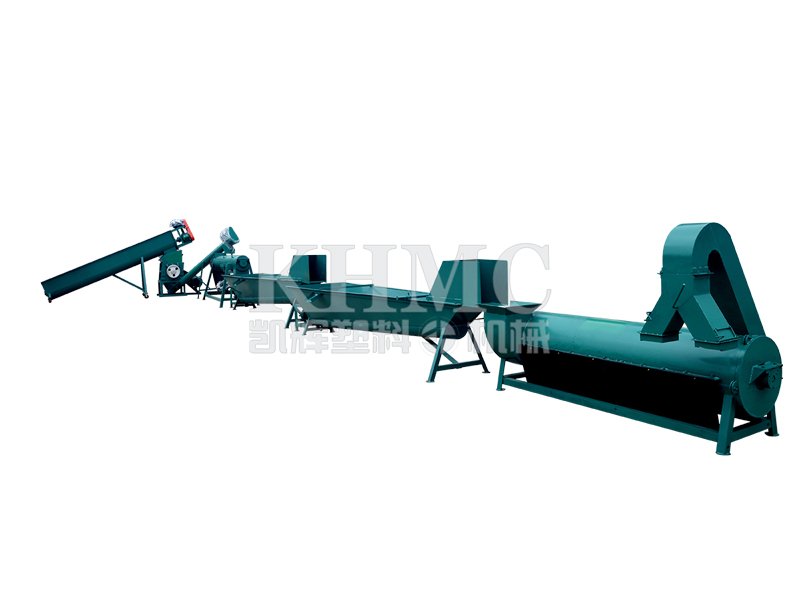

Function

The pet bottle recycling machine can produce pet flakes by a working process of label moving—crushing—washing—drying. Meanwhile, as the water bottle is made of PET, while the cap is made of PE, the cap flakes is also a very high-quality recycled raw material as a by-product of the production line. It can be directly mixed into PE granules to produce PE products, or to be processed into granules to improve product quality and added value.

Classification

The pet bottle recycling line has two types, cold washing type and hot washing type.

Cold washing – As the name suggests, the water used for washing is cold water at room temperature. The equipment cost is relatively low, and the finished product flakes can be used to produce plastic rope, brush wire, etc.

Hot washing – Compared with cold washing, the equipment has a heating furnace to increase the temperature of the washing water, and the produced flakes are cleaner, especially suitable for dirty raw materials containing grease and sundries. The finished products are mainly used for chemical fiber processing and textile industry.

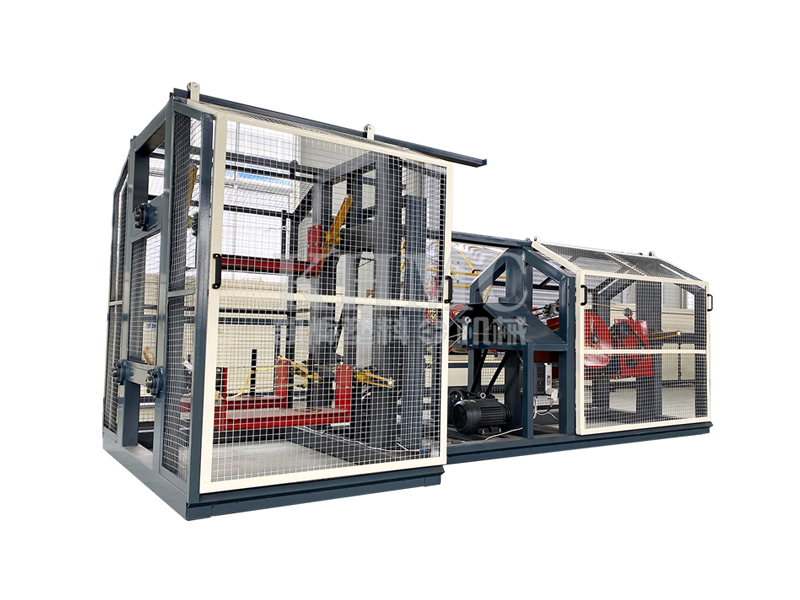

Product detail pictures:

Related Product Guide:

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for High-Quality Yarn Balling Machine Factory – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery , The product will supply to all over the world, such as: Pretoria, Australia, Luxembourg, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.