High-Quality Two For One Twister Machine Supplier – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery

High-Quality Two For One Twister Machine Supplier – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery Detail:

Technical Parameters

|

Conveyor |

Label remover |

Conveyor |

Screw feeder |

Crusher |

|

|

Power |

1.5kw |

15kw |

1.5kw |

4kw |

22kw |

|

Size |

4m*0.7m |

4m*Φ0.63m |

4m*0.7m |

4m*0.5m |

#612 |

|

Screw Loader |

Frictional washer |

1st Floating washer |

2nd Floating washer |

Water extractor |

|

|

Power |

2.2kw-6 |

7.5kw |

2.2-4kw |

2.2-4kw |

15kw |

|

Size |

3m*Φ0.219m |

3m*Φ0.377m |

4m*1m |

4m*1m |

2.5m*Φ0.56m |

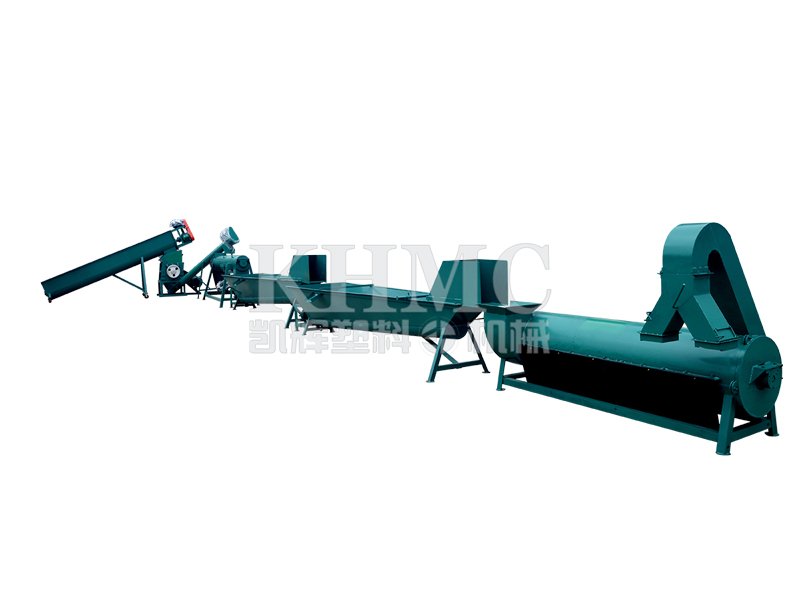

Function

The pet bottle recycling machine can produce pet flakes by a working process of label moving—crushing—washing—drying. Meanwhile, as the water bottle is made of PET, while the cap is made of PE, the cap flakes is also a very high-quality recycled raw material as a by-product of the production line. It can be directly mixed into PE granules to produce PE products, or to be processed into granules to improve product quality and added value.

Classification

The pet bottle recycling line has two types, cold washing type and hot washing type.

Cold washing – As the name suggests, the water used for washing is cold water at room temperature. The equipment cost is relatively low, and the finished product flakes can be used to produce plastic rope, brush wire, etc.

Hot washing – Compared with cold washing, the equipment has a heating furnace to increase the temperature of the washing water, and the produced flakes are cleaner, especially suitable for dirty raw materials containing grease and sundries. The finished products are mainly used for chemical fiber processing and textile industry.

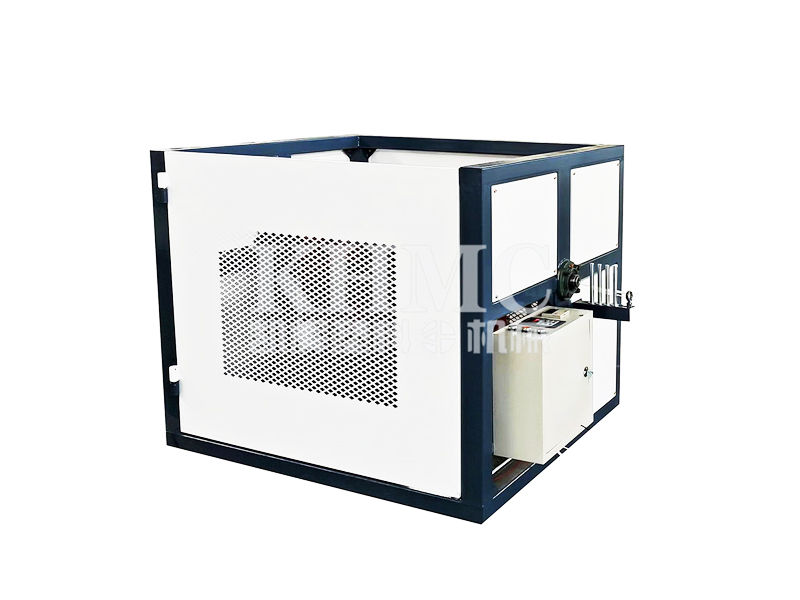

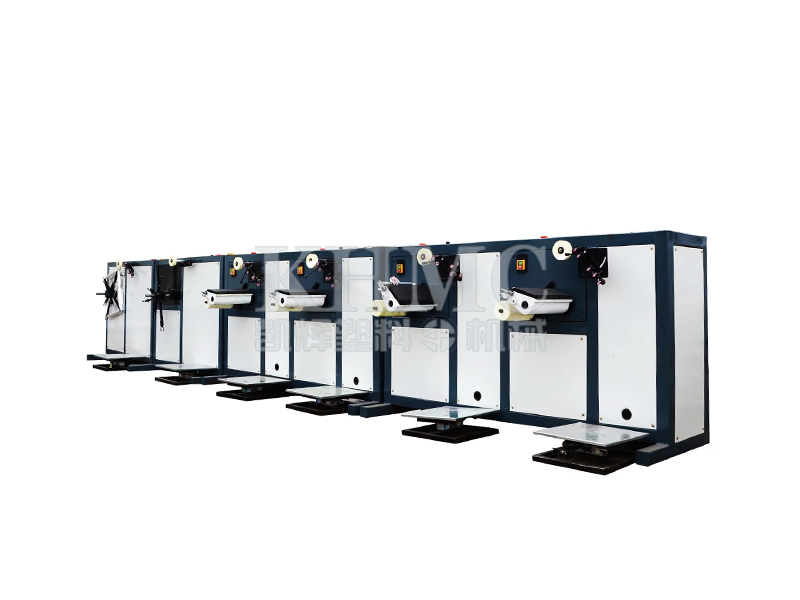

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for High-Quality Two For One Twister Machine Supplier – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery , The product will supply to all over the world, such as: Ethiopia, Sacramento, Algeria, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.