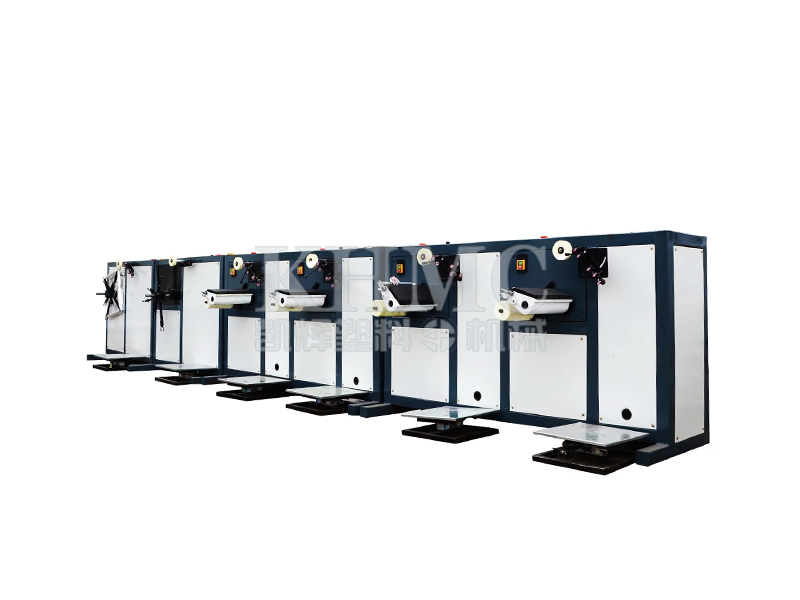

High-Quality Monofilament Extrusion Machine Factory – Automatic Plastic Pp Twine Pe Rope Hank Winding Machine – Kaihui Machinery

High-Quality Monofilament Extrusion Machine Factory – Automatic Plastic Pp Twine Pe Rope Hank Winding Machine – Kaihui Machinery Detail:

Technical Parameters

|

Model |

KHHW-01 |

KHHW-02 |

KHHW-03 |

|

Scope |

3-6mm |

8-12mm |

12-16mm |

|

Machine Size |

3.1*1.6*2.1m |

3.1*1.6*2.1m |

3.1*1.6*2.1m |

|

Winding Speed |

0-150m/min |

0-150m/min |

0-150m/min |

|

Total Power |

1.9kw |

2.25 kw |

2.25 kw |

|

Controlling System |

PLC control |

||

|

Working voltage |

380v, 220 V or customized as you need. |

||

Function

The machine is suitable for winding different size of PP, PE, PET braided rope, twisted rope and twisted twine into hank shape. It is generally used for the processing and production of clothesline, outdoor equipment rope, climbing rope, emergency escape rope, rescue rope, aerial work rope, etc. It can also be used for processing hemp rope and cotton thread which are used for DIY handiwork.

Advantages

–Rope hank size can be adjusted easily

–High degree of automation

–Easy to operate and maintain

–High speed with high productivity

–High quality with long lifespan

–Advanced technology with low noise

–Mass production with low cost and price

More Choices

KHMC provides different types of rope winding & rewinding machines, include rope ball winding machine, rope spool winding machine, twisted rope winding machine, rope hank winding machine, etc. These machineries help to make the thread yarn into ball shape, roll shape, olive shape, cross shape, spool shape, bobbin shape, coil shape, Coil winder is also available to make big rope reel into small coils.

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for High-Quality Monofilament Extrusion Machine Factory – Automatic Plastic Pp Twine Pe Rope Hank Winding Machine – Kaihui Machinery , The product will supply to all over the world, such as: Hongkong, kazan, Bolivia, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.