High-Quality Hay Baler Twine Machine Manufacturers – Automatic Plastic Pp Twine Pe Rope Hank Winding Machine – Kaihui Machinery

High-Quality Hay Baler Twine Machine Manufacturers – Automatic Plastic Pp Twine Pe Rope Hank Winding Machine – Kaihui Machinery Detail:

Technical Parameters

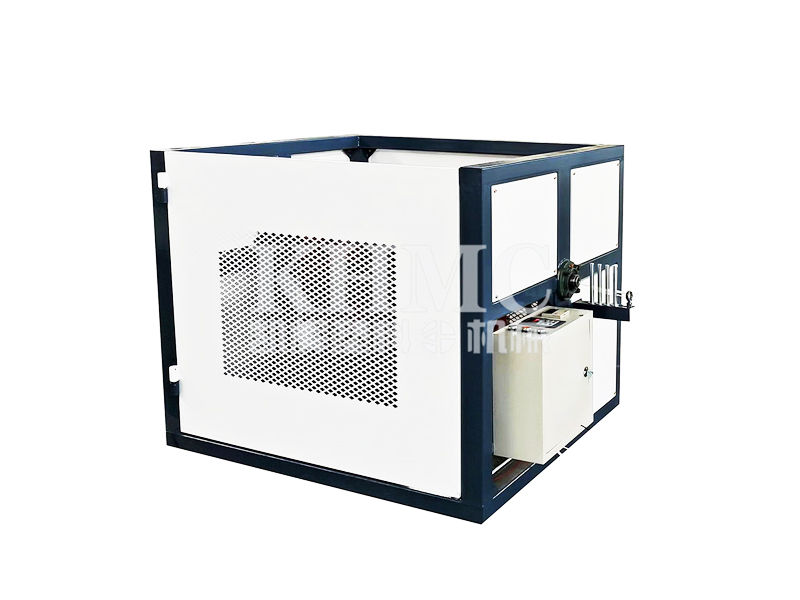

|

Model |

KHHW-01 |

KHHW-02 |

KHHW-03 |

|

Scope |

3-6mm |

8-12mm |

12-16mm |

|

Machine Size |

3.1*1.6*2.1m |

3.1*1.6*2.1m |

3.1*1.6*2.1m |

|

Winding Speed |

0-150m/min |

0-150m/min |

0-150m/min |

|

Total Power |

1.9kw |

2.25 kw |

2.25 kw |

|

Controlling System |

PLC control |

||

|

Working voltage |

380v, 220 V or customized as you need. |

||

Function

The machine is suitable for winding different size of PP, PE, PET braided rope, twisted rope and twisted twine into hank shape. It is generally used for the processing and production of clothesline, outdoor equipment rope, climbing rope, emergency escape rope, rescue rope, aerial work rope, etc. It can also be used for processing hemp rope and cotton thread which are used for DIY handiwork.

Advantages

–Rope hank size can be adjusted easily

–High degree of automation

–Easy to operate and maintain

–High speed with high productivity

–High quality with long lifespan

–Advanced technology with low noise

–Mass production with low cost and price

More Choices

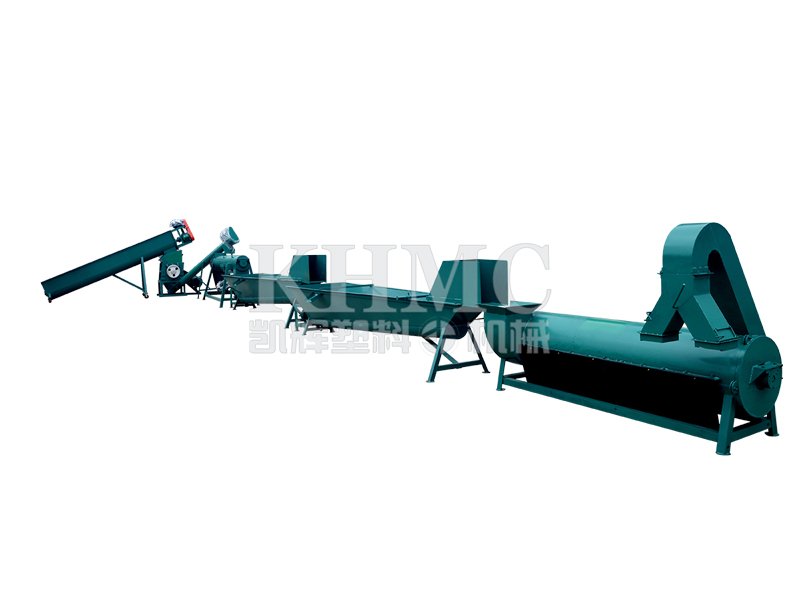

KHMC provides different types of rope winding & rewinding machines, include rope ball winding machine, rope spool winding machine, twisted rope winding machine, rope hank winding machine, etc. These machineries help to make the thread yarn into ball shape, roll shape, olive shape, cross shape, spool shape, bobbin shape, coil shape, Coil winder is also available to make big rope reel into small coils.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for High-Quality Hay Baler Twine Machine Manufacturers – Automatic Plastic Pp Twine Pe Rope Hank Winding Machine – Kaihui Machinery , The product will supply to all over the world, such as: Sao Paulo, Ghana, Bangkok, We have customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don't hesitate to contact us.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.