High-Quality Crimped Filament Machine Manufacturers – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery

High-Quality Crimped Filament Machine Manufacturers – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery Detail:

Technical Parameters

|

Conveyor |

Label remover |

Conveyor |

Screw feeder |

Crusher |

|

|

Power |

1.5kw |

15kw |

1.5kw |

4kw |

22kw |

|

Size |

4m*0.7m |

4m*Φ0.63m |

4m*0.7m |

4m*0.5m |

#612 |

|

Screw Loader |

Frictional washer |

1st Floating washer |

2nd Floating washer |

Water extractor |

|

|

Power |

2.2kw-6 |

7.5kw |

2.2-4kw |

2.2-4kw |

15kw |

|

Size |

3m*Φ0.219m |

3m*Φ0.377m |

4m*1m |

4m*1m |

2.5m*Φ0.56m |

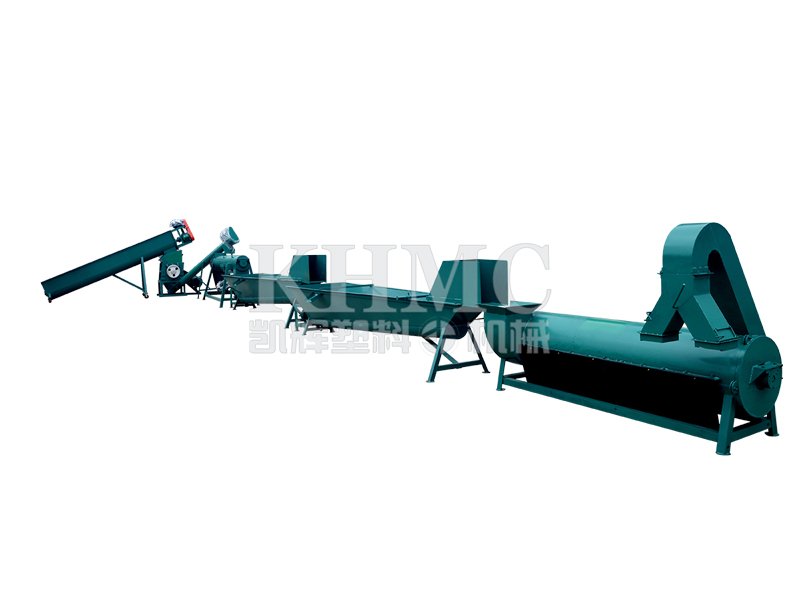

Function

The pet bottle recycling machine can produce pet flakes by a working process of label moving—crushing—washing—drying. Meanwhile, as the water bottle is made of PET, while the cap is made of PE, the cap flakes is also a very high-quality recycled raw material as a by-product of the production line. It can be directly mixed into PE granules to produce PE products, or to be processed into granules to improve product quality and added value.

Classification

The pet bottle recycling line has two types, cold washing type and hot washing type.

Cold washing – As the name suggests, the water used for washing is cold water at room temperature. The equipment cost is relatively low, and the finished product flakes can be used to produce plastic rope, brush wire, etc.

Hot washing – Compared with cold washing, the equipment has a heating furnace to increase the temperature of the washing water, and the produced flakes are cleaner, especially suitable for dirty raw materials containing grease and sundries. The finished products are mainly used for chemical fiber processing and textile industry.

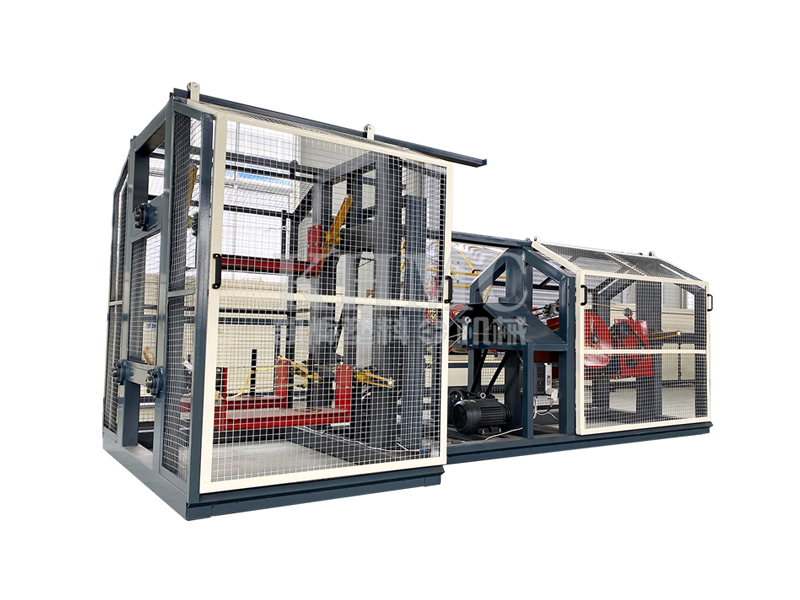

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for High-Quality Crimped Filament Machine Manufacturers – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery , The product will supply to all over the world, such as: Turkmenistan, Hungary, Saudi Arabia, Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.