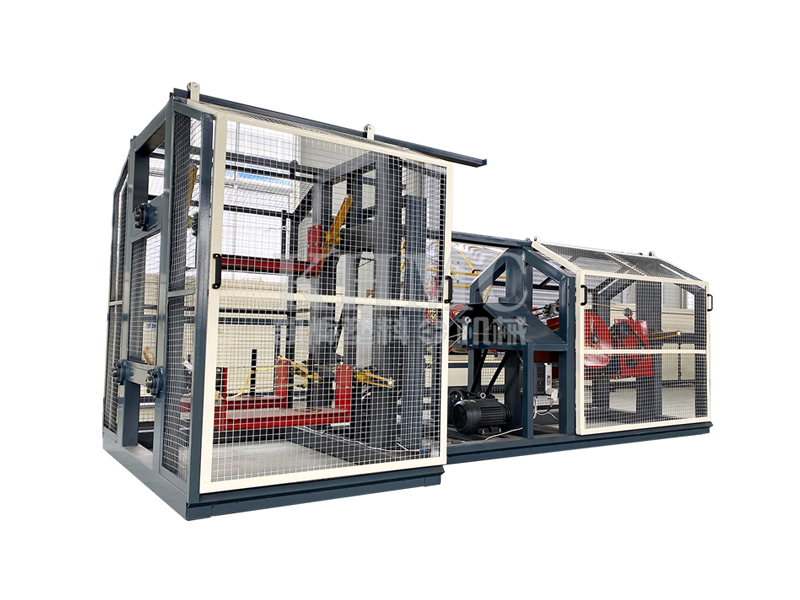

Factory Made Hot-sale Pet Plastic Broom Filament Making Machine

We believe that extended time period partnership can be a result of high quality, worth added service, wealthy knowledge and personal contact for Factory Made Hot-sale Pet Plastic Broom Filament Making Machine, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services.

We believe that extended time period partnership can be a result of high quality, worth added service, wealthy knowledge and personal contact for China Machine and Extruder Machine, Faced with the vitality of the global wave of economic integration, we’ve been confident with our high-quality merchandise and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

Technical Parameters

| Type |

SYP(T)-B65 |

SYP(T)-B80 |

SYP(T)-B90 |

SYP(T)-B110 |

SYP(T)-B125 |

|

| Screw Diameter(mm) |

65 |

80 |

90 |

110 |

125 |

|

| Gross power(kw) |

90 |

100 |

130 |

150 |

170 |

|

| Actual power consumption (kw) |

40 |

50 |

65 |

70 |

85 |

|

| Productivity(kg/h) |

PP |

30-50 |

40-70 |

60-90 |

100-140 |

100-140 |

|

PET |

50-70 |

80-90 |

100-125 |

130-160 |

160-200 |

|

| Dimensions(m) |

L: 20-25, W: 2-3, H: 2-3 |

|||||

|

It can be designed according to workshop size. |

||||||

| Total weight(t) |

7.5 |

8.2 |

9.6 |

10.8 |

12.8 |

|

Function

The brush filament production line is to make filaments for all kinds of brushes and brooms, like scrub brush, bristle brush, toilet brush, road sweeper brush, Christmas tree pine needle, etc.

Product Video

Production Process of Extruding Part

The mixing dryer – The extruder – The cold water tank – The first traction part – The first stretching part (hot water tank)- The second traction part – The second stretching part(oven) – The winders.

Auxiliary Equipment

Oven: Makes filaments more supple and straight

Cutter: Cut the wrapped filament into agreed small pieces

More auxiliary equipment is available to change the shape of the product and improve the quality of the product. Different products have slight difference in production processes and requires different auxiliary machines. We will recommend according to the actual situation. You are welcomed to contact with us to get advices.

We believe that extended time period partnership can be a result of high quality, worth added service, wealthy knowledge and personal contact for Factory made hot-sale Pet Plastic Broom Filament Making Machine, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services.

Factory made hot-sale China Machine and Extruder Machine, Faced with the vitality of the global wave of economic integration, we’ve been confident with our high-quality merchandise and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.