China Plastic Granulation Machine – High Quality Plastic Strap Making Machine PP PET Straps Production Line – Kaihui Machinery

China Plastic Granulation Machine – High Quality Plastic Strap Making Machine PP PET Straps Production Line – Kaihui Machinery Detail:

Technical Parameters

| Type |

TSJ-P |

TSJ-T |

STJ-ABA |

| Screw Diameter(mm) |

Ф65/80/90 |

Ф80/90 |

Ф40+80/90 |

| Finished products |

PP strap |

PET strap |

Cored strap |

| Output (ton/day) |

1-3T |

2.5-4.5T |

2-4T |

| Installation Size (m) |

L: 15-25, W: 2-4, H: 2-3 |

||

| Total weight(t) |

6.2 |

8.9 |

9.6 |

Function

The straps made by our machine are suitable for both manual packing and automatic packer. The straps are widely used to secure cartons, wooden box, bricks, etc. The application scenarios of PET packing tape and PP packing are different. PET packing belts are generally used for bundling large-volume and heavy-weight goods such as masonry, wood, wooden boxes, pallets, etc., while PP packing belts are generally used for bundling and fixing household appliances, furniture, logistics packaging cartons, etc.

Advantages

Our machine helps customers reduce cost by using cheaper materials and saving labor cost. The strap making machine produced by our company are suitable for new materials, regenerated granules, regenerated flakes, and a mixer which adds a fixed proportion of calcium carbonate powder to reduce the cost of raw materials. The production line is easy for operation, entire production line only one operator, saving labor cost. Production formulas are provided free of charge and the technicians guide for operation are available.

More Choices

Our company has double extrusion equipment and triple extrusion equipment, which can produce two-color packing belts. Its products are used in handicraft production and special packaging industries. Packing belts produced by three-color extruder with core-spun process can effectively reduce the cost of raw materials.

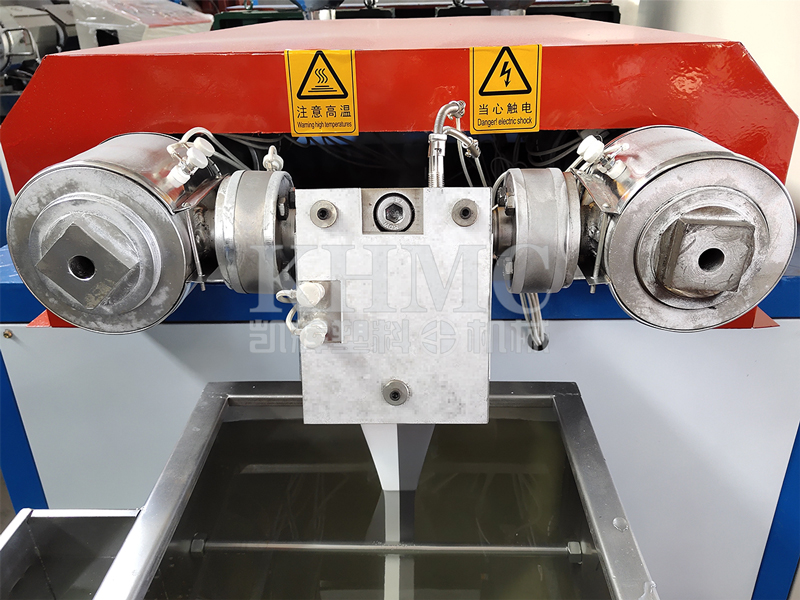

Product detail pictures:

Related Product Guide:

We emphasize development and introduce new products into the market every year for China Plastic Granulation Machine – High Quality Plastic Strap Making Machine PP PET Straps Production Line – Kaihui Machinery , The product will supply to all over the world, such as: South Africa, Florence, New York, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.