China Hay Baler Twine Machine Manufacturer – High Efficiency Plastic Recycling Granulator Machine – Kaihui Machinery

China Hay Baler Twine Machine Manufacturer – High Efficiency Plastic Recycling Granulator Machine – Kaihui Machinery Detail:

Technical Parameters

|

Type |

SJ-125/S |

SJ-125/D |

SJ-150/D |

SJ-180/D |

SJ-210/D |

|

Screw size |

125mm |

125mm/125mm |

150mm/125mm |

150mm/150mm |

210mm/180mm |

|

Extruder |

Single |

Double |

Double |

Double |

Double |

|

Main motor power |

30kw |

22kw |

45kw |

75kw |

110kw |

|

11kw |

22kw |

30kw |

45kw |

||

|

Reducer |

200 |

200 200 |

250 225 |

280 250 |

325 280 |

|

Filter |

Manual filter / electric filter |

Hydraulic filter |

|||

|

Capacity |

3000kg |

3000kg |

5000kg |

8000kg |

10000kg |

|

Machine Size |

3000*2000*1000 |

3000*2500*1500 |

3500*3500*2000 |

5000*4000*2000 |

7000*5000*2000 |

|

Crusher, automatic loader, washing machine, moving silo can be provide if you need . |

|||||

Equipment and Services

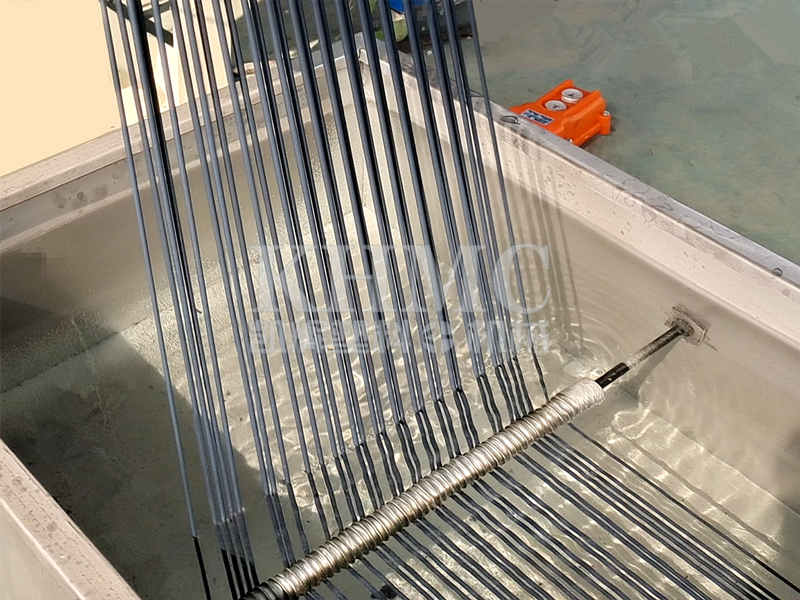

Our plastic granulation machine is to make granules by a process of crushing—washing—melting—extruding—cutting—storing. While providing automatic cleaning equipment, our company can also provide customers with factory self-built cleaning pool solutions to save transportation costs.

Product Video

More Choices

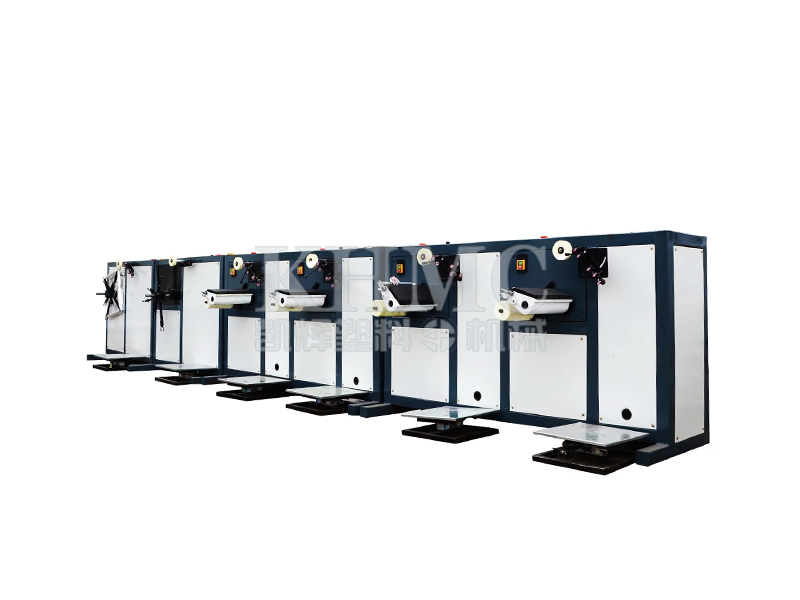

Our company can produce machines with equipment capacity ranging from 2 tons to 12 tons, from simple equipment to high-end machines, which can meet the requirements of most customers. The optimal solution can be designed and customized according to the customer’s raw material types and production capacity requirements.

Single-step granulator, two-step granulator and three-step granulator are optional. At the same time, in terms of equipment configuration, ceramic heating, cast aluminum heating, electromagnetic energy-saving heating are optional; electric screen changer, hydraulic single-screen screen changer, and hydraulic uninterrupted screen changer are optional. Various functions such as automatic feeding, intelligent temperature control, automatic pressure sensing slag discharge (impurities), automatic water circulation cooling, automatic material storage and other functions are optional, with a high degree of automation, helping customers to increase production and efficiency.

Product detail pictures:

Related Product Guide:

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for China Hay Baler Twine Machine Manufacturer – High Efficiency Plastic Recycling Granulator Machine – Kaihui Machinery , The product will supply to all over the world, such as: Lithuania, Benin, Swansea, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.