Best-Selling Automatic Yarn Ball Winding Machine Factory – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery

Best-Selling Automatic Yarn Ball Winding Machine Factory – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery Detail:

Technical Parameters

|

Conveyor |

Label remover |

Conveyor |

Screw feeder |

Crusher |

|

|

Power |

1.5kw |

15kw |

1.5kw |

4kw |

22kw |

|

Size |

4m*0.7m |

4m*Φ0.63m |

4m*0.7m |

4m*0.5m |

#612 |

|

Screw Loader |

Frictional washer |

1st Floating washer |

2nd Floating washer |

Water extractor |

|

|

Power |

2.2kw-6 |

7.5kw |

2.2-4kw |

2.2-4kw |

15kw |

|

Size |

3m*Φ0.219m |

3m*Φ0.377m |

4m*1m |

4m*1m |

2.5m*Φ0.56m |

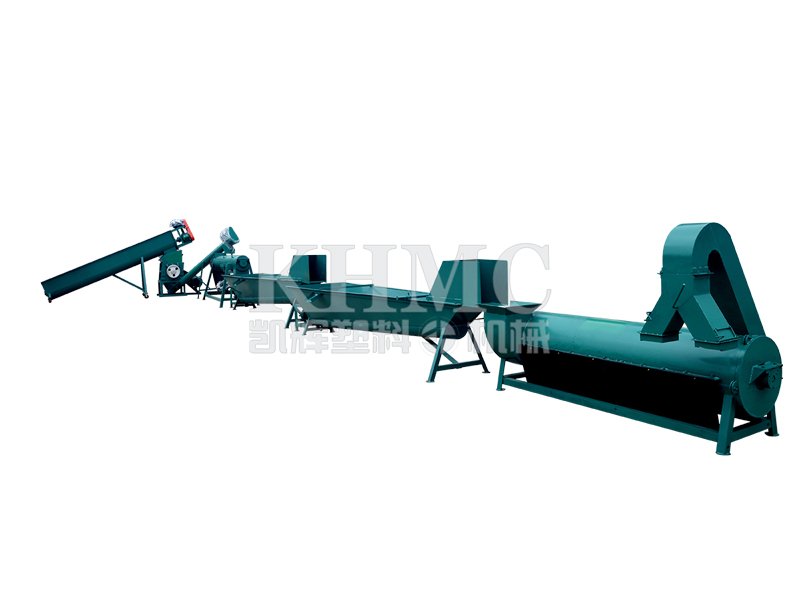

Function

The pet bottle recycling machine can produce pet flakes by a working process of label moving—crushing—washing—drying. Meanwhile, as the water bottle is made of PET, while the cap is made of PE, the cap flakes is also a very high-quality recycled raw material as a by-product of the production line. It can be directly mixed into PE granules to produce PE products, or to be processed into granules to improve product quality and added value.

Classification

The pet bottle recycling line has two types, cold washing type and hot washing type.

Cold washing – As the name suggests, the water used for washing is cold water at room temperature. The equipment cost is relatively low, and the finished product flakes can be used to produce plastic rope, brush wire, etc.

Hot washing – Compared with cold washing, the equipment has a heating furnace to increase the temperature of the washing water, and the produced flakes are cleaner, especially suitable for dirty raw materials containing grease and sundries. The finished products are mainly used for chemical fiber processing and textile industry.

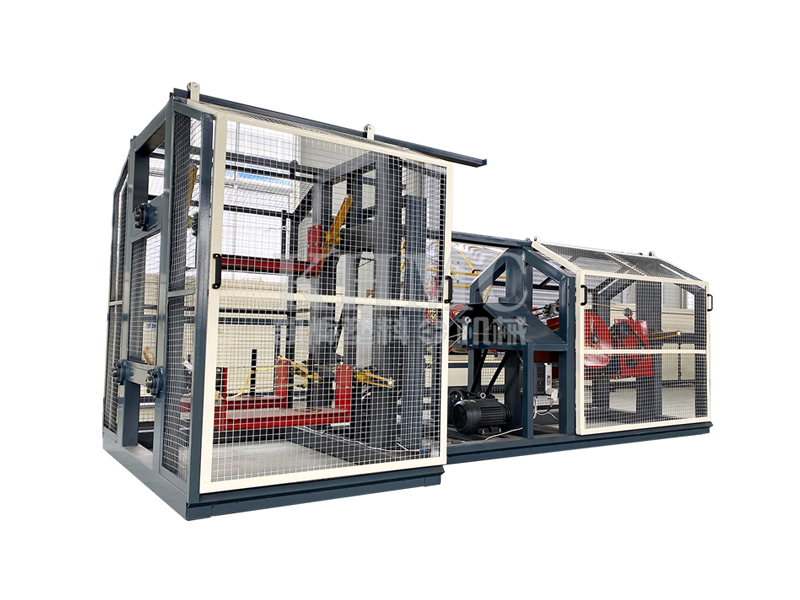

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Best-Selling Automatic Yarn Ball Winding Machine Factory – Plastic Bottle Crushing Recycling Machine For PET Flakes Production – Kaihui Machinery , The product will supply to all over the world, such as: Hongkong, Cape Town, Lyon, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.